Manufacturing Scope 2 Emissions Management

Addressing Industrial Energy Challenges

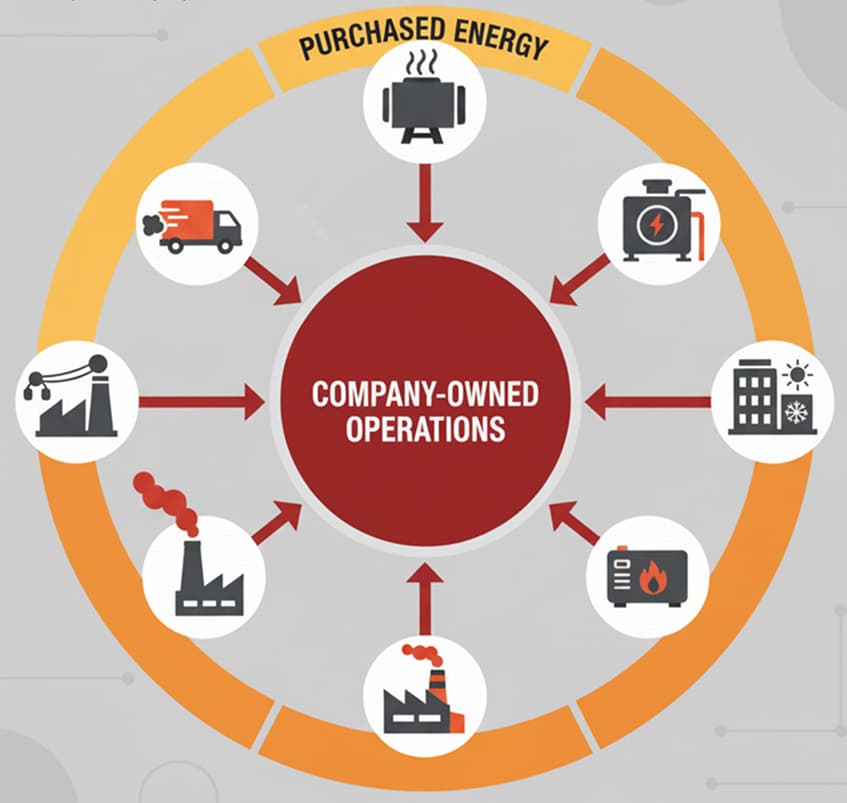

Manufacturing facilities represent some of the largest consumers of purchased electricity globally, making Scope 2 emissions a critical component of industrial decarbonization strategies. The sector's diverse energy needs - from process heating to machinery operation - create both challenges and opportunities for emissions reduction.

Understanding Manufacturing Energy Profiles

Manufacturing operations typically exhibit complex energy consumption patterns shaped by production schedules, equipment requirements, and process demands. Heavy industries like steel, aluminum, and chemicals are particularly electricity-intensive, while lighter manufacturing may have more variable loads. Understanding these profiles is essential for developing targeted reduction strategies.

Baseline Assessment: Start by conducting comprehensive energy audits to identify consumption patterns, peak demand periods, and efficiency opportunities. Map energy use to specific processes and production lines to prioritize interventions.

Key Strategies for Manufacturing Scope 2 Reduction

On-site Renewable Generation: Many manufacturing facilities have substantial roof space and land suitable for solar installations. Combined with battery storage, on-site generation can significantly reduce grid dependence while providing energy resilience.

Power Purchase Agreements (PPAs): Long-term PPAs provide price stability and guaranteed renewable energy supply. Manufacturing companies with predictable, high energy consumption are ideal candidates for direct PPAs with renewable energy developers.

Energy Efficiency Improvements: Upgrading to high-efficiency motors, implementing variable frequency drives, optimizing compressed air systems, and improving process controls can reduce overall electricity demand by 20-30% in many facilities.

Load Shifting and Demand Response: Where production flexibility exists, shifting energy-intensive processes to periods of high renewable energy availability or low grid carbon intensity can reduce emissions without changing total consumption.

Overcoming Manufacturing-Specific Challenges

Reliability Requirements: Many manufacturing processes cannot tolerate power interruptions. Solutions include redundant renewable sources, battery backup systems, and maintaining grid connections for critical loads.

Capital Constraints: Energy projects compete with production investments for capital. Demonstrating ROI through energy cost savings, available incentives, and risk mitigation helps build the business case.

Global Operations: Manufacturers with facilities across multiple countries face varying grid compositions and renewable energy availability. Develop region-specific strategies while maintaining corporate-wide targets.

Implementation Roadmap

- Conduct Energy Mapping: Detailed assessment of current consumption and emissions

- Set Science-Based Targets: Establish clear Scope 2 reduction goals aligned with 1.5°C pathways

- Prioritize Quick Wins: Implement energy efficiency measures with rapid payback

- Develop Renewable Strategy: Evaluate and pursue optimal mix of on-site, off-site, and certificate options

- Engage Supply Chain: Work with suppliers on renewable energy adoption

- Monitor and Report: Track progress using recognized frameworks and standards

Technology Solutions and Innovations

Emerging technologies are expanding manufacturing's Scope 2 reduction options. Smart factory systems optimize energy use in real-time, while industrial IoT enables granular monitoring and control. Electrification of previously fossil-fuel-dependent processes, such as industrial heating, creates new opportunities for renewable electricity to displace direct emissions.

Case Examples and Best Practices

Leading manufacturers are demonstrating the feasibility of ambitious Scope 2 targets. Companies achieving 100% renewable electricity combine multiple strategies: large-scale solar installations, participation in utility green tariff programs, strategic use of RECs for remaining gaps, and continuous efficiency improvements. Success factors include executive commitment, dedicated sustainability teams, and integration of energy management into operational excellence programs.

The Business Case

Beyond emissions reduction, manufacturing Scope 2 initiatives deliver tangible business benefits including energy cost stability, operational resilience, enhanced brand value, and improved competitiveness in sustainability-conscious markets. As renewable energy costs continue declining and efficiency technologies advance, the economic case for action strengthens.